FM printing, or known as Stochastic printing, has always been the most perfect screen adjustment method for all printers.

Traditional film printing technology cannot perfectly realize FM screen printing. The emergence of CTP solves many problems in FM screen printing production, but the stability of repeated production is difficult. At present, our company uses Kodak CTP direct plate making machine “Trendsetter” with Kodak’s proud SquareSpot imaging technology, together with the best combination of KODAK SONORA X no-wash plate material, which makes FM screen printing a better solution for stable and repeatable production.

FM frequency modulation network is a fixed distance point size expression method relative to AM amplitude modulation network technology, but uses finer fine points (20μ and 10μ), and uses random pattern parameters to make different density arrangements, so it can avoid AM networks The four-color CMYK must be misaligned with different screen angles, so four-color, six-color, seven-color, and eight-color printing does not have to turn the angle to avoid the wrong (collision) network situation, which solves the problem of screen collision in multi-color printing. Many problems such as moiré and moiré stripes have also greatly improved the details and level of the image.

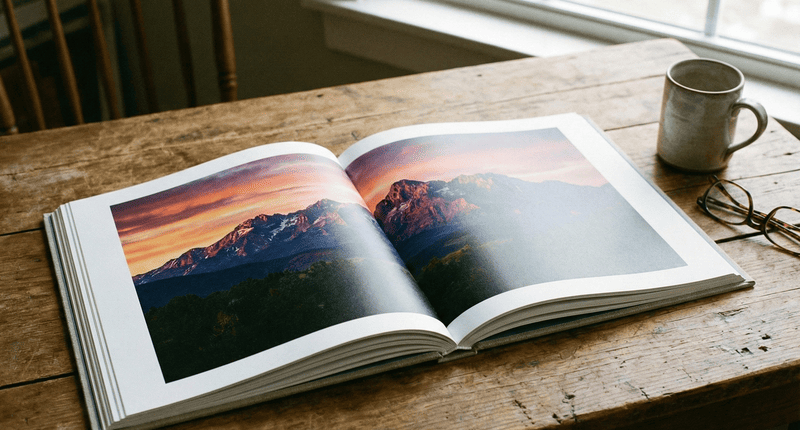

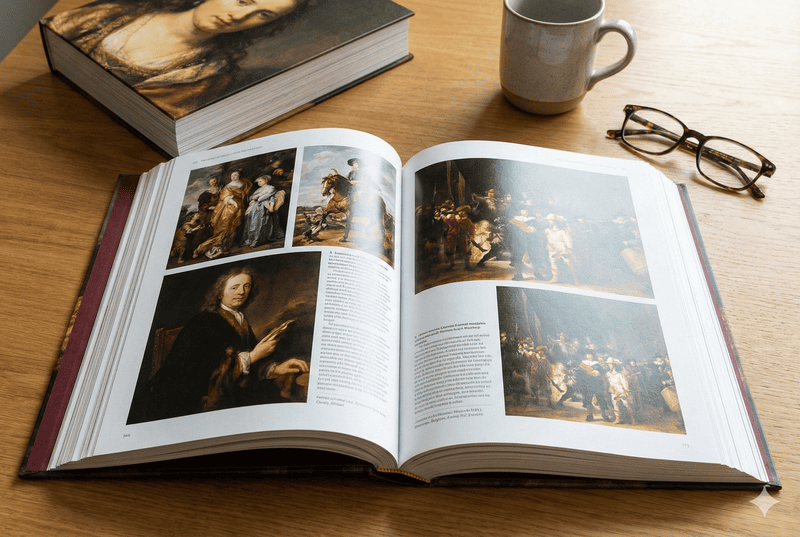

FM Printing is suitable for the production of image art albums. The pictures have large margins and high sharpness, such as steel, metal, rock, oil paintings and densely colored landscape figures, as well as mesh fans, air conditioners, bicycles, jewelry, and text And fine pictures, etc., using FM screen printing has very good expressive power. At the same time, when some customers have extremely high color requirements when using Hi Fi Color, they must use six-color or seven-color printing. FM network is more conducive to this development.

Note: Using FM network production cost description: the attention of plate making and printing must be strengthened, and the selectivity of printing conditions is stricter (better paper, ink, printing equipment), and the cost of plate making will increase by 10 to 20%, while printing It is appropriate to estimate 15 to 25% of the cost