Proudly Served

A board book is a type of book made with thick, durable cardboard pages, designed to withstand heavy use. While commonly used for children’s books, board books can also be utilized for other purposes, such as promotional materials, educational tools, or specialty publications where durability is key.

How Board Books Are Made?

The typical procedure of manufacturing a hardcover book includes prepress, printing, folding, collating, dot glueing and board mounting. Such a complex process requires advanced machinery and seasoned expertise.

With 36 years in the industry, Huaxin Printing offers a one-stop in-house manufacturing solution, eliminating the need for outsourcing. Our specialized color management ensures your product meets the highest standards.

Prepress

Elevate your print projects with advanced prepress experience and compliance with ISO 12647-7 color management standard.

Printing

Fully automated printing presses with the speed of up to 18,000 sheets per hour. CIP-3 ink management and experienced press operators.

Collating

Precisely aligning and stacking the printed pages in the correct order, ensuring consistency and accuracy before they are bound together.

Dot Gluing

Dot gluing in board book manufacturing secures pages together by applying small adhesive dots, ensuring durable binding without excess glue.

Mounting

Automatically attaching printed sheets onto thick cardboard, ensuring precise alignment and a smooth, durable finish for each page

Flattening

Pressing the assembled pages to ensure even thickness and a smooth, flat surface, enhancing the book’s overall durability.

Our Works

Binding for Board Books

Board books are unique in their construction since they aren’t traditionally bound. Instead, the “pages” are glued together, and a final printed sheet is adhered to the first and last boards, covering the “spine” to create the cover—this is known as a “self-covered” board book. However, if you prefer a hardcover, we can add one, which is a popular option.

For a hardcover board book, we recommend using 157gsm / 106 lb art paper wrapped on greyboard, bound similarly to a standard hardcover book. The default cover will have square corners, but you may opt for rounded corners on the inner pages. We can also customize the hardcover with rounded corners, though this involves extra labor as it requires hand-wrapping, which increases the cost.

Additionally, you may select to insert a layer of sponge within the front and back covers for a “padded” effect. This not only makes the book appear thicker and softer but also enhances its appeal to children. For safety and environmental reasons, we use only non-toxic, soy-based inks, and we suggest applying a gloss coating rather than lamination. Laminating could lead to the film peeling, posing a potential hazard if swallowed.

Softcover Board Book

Hardcover Board Books

Pop-Up Board Books

There’s an innovative type of pop-up board book features sturdy pages and interactive flaps, making it durable and engaging for young readers. The colorful illustrations and hidden surprises beneath the flaps encourage exploration, enhancing both learning and enjoyment. It’s an excellent educational tool, ideal for early childhood development.

Book Sizes

Board books can be designed at many different types of sizes, be it square, portrait and landscape. Whatever the size may be, it is always essential that the books must provide sturdy, small-sized pages ideal for durability and ease of handling across various audiences. Below are some commonly used sizes for board books:

| Type | Size 1 | Size 2 | Size 3 | Size 4 | Size 5 |

|---|---|---|---|---|---|

| Square | 6"*6" (152*152mm) | 6.5"*6.5" (165*165mm) | 7"*7" (178*178mm) | 7.5"*7.5" (191*191mm) | 8"*8" (203*203mm) |

| Portrait | 5.5"*8" (140*203mm) | 6"*7" (152*178mm) | 6"*8" (152*203mm) | 6"*9" (152*229mm) | 7"*10" (178*254mm) |

| Landscape | 8“*5.5“ (203*140mm) | 7"*6" (178*152mm) | 8"*6" (203*152mm) | 9"*6" (229*152mm) | 10"*7" (254*178mm) |

Designing Tips

For children’s board books, the artwork is crucial. To captivate young readers, ensure the interior illustrations are vibrant and the cover is eye-catching. Whether you are creating the artwork yourself or hiring a professional, it’s vital to prepare the files correctly for printing. This involves understanding bleed zones, safety areas, trim lines, borders, and ensuring the correct resolution and color space.

A skilled book designer will manage these technical aspects, including digitizing traditional artwork, and we will meticulously review your files before printing. However, it’s essential that you provide “print-ready” files. Don’t worry, though—we’ll guide you through the process, clarify requirements, and coordinate with your designer to ensure a flawless print. Below are key tips for preparing a board book that your designer should consider.

Here are key tips for file preparation to achieve optimal printing results.

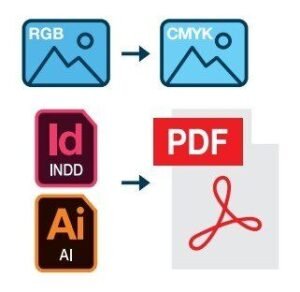

For optimal printing outcomes, it’s advisable to save your files in PDF format as vectors. We suggest using Adobe Illustrator or Adobe InDesign for hardcover book design. These platforms also enable the conversion of color space from RGB to CMYK, a requirement for offset printing.

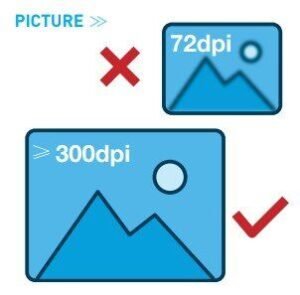

In cases where vector files are not an option, such as when using bitmaps from Photoshop, maintaining a resolution of at least 300 DPI is crucial. Unlike vectors, raster images need to be high-definition to avoid quality loss during resizing.

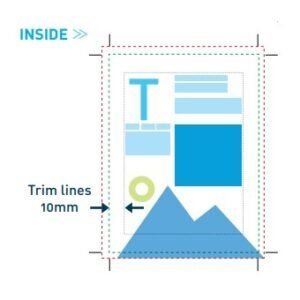

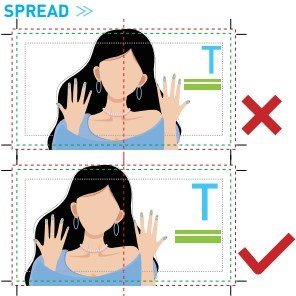

Within your designated bleed zone, it’s imperative to identify the trim lines that outline the final size of the completed page. Keep essential page elements at least 10 mm away from these lines for optimal results.

When a photo or artwork extends across a two-page spread, ensure that critical elements, such as facial features or key details, do not fall on the central fold.

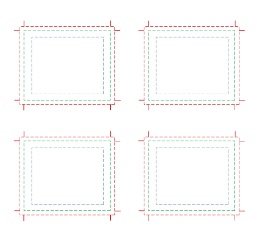

When designing your board book, make sure to set your layout to “facing pages.”

Ensure uniformity in all formatting elements across the document, including but not limited to fonts, font sizes, drop caps, section dividers, page numbers, margins, chapter titles, and page breaks.

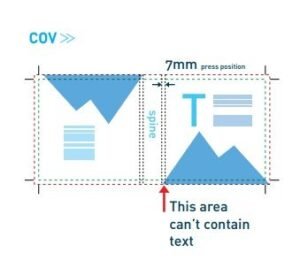

Make sure that there should be an extra 7mm alongside the cover file for wrapping over the board. Plus, there should be no text along the two edges of the spine.

Pricing

Hardcover Board Book Prices

| Pages (Cover+Text) | 500 Copies | 1,000 Copiees | 2,000 Copies | 5,000 Copies |

|---|---|---|---|---|

| 16 Pages | USD 2.45 | USD 1.78 | USD 1.48 | USD 1.15 |

| 24 Pages | USD 2.65 | USD 2.10 | USD 1.80 | USD 1.39 |

| 32 Pages | USD 3.38 | USD 2.59 | USD 2.16 | USD 1.71 |

Remarks

- All prices above are the unit prices corresponding to the number of text pages and print-runs;

- All prices are EXW our facility and do not include shipping costs.

- Cover: 3 mm thick gray board cover; Wrapped with 157 gsm / 100 lb coated cover sheet with gloss lamination

- Inner: 350 gsm / 16 pt C1S stock with gloss or matte lamination on all interior pages

- Cover and inner: full color printing

- Packed no more than 18kg/carton, no shrinkwrapping

Softover Board Book Prices

| Pages (Cover+Text) | 500 Copies | 1,000 Copiees | 2,000 Copies | 5,000 Copies |

|---|---|---|---|---|

| 20 Pages | USD 1.95 | USD 1.45 | USD 1.20 | USD 0.92 |

| 24 Pages | USD 2.02 | USD 1.52 | USD 1.29 | USD 0.98 |

| 30 Pages | USD 2.63 | USD 2.08 | USD 1.70 | USD 1.32 |

Remarks

- All prices above are the unit prices corresponding to the number of text pages and print-runs;

- All prices are EXW our facility and do not include shipping costs.

- 350 gsm / 16 pt C1S stock with gloss or matte lamination on all pages

- Cover and inner: full color printing

- Packed no more than 18kg/carton, no shrinkwrapping

Finishing

In the book production process, cover finishing is a vital element that enhances both the visual appeal and durability of the product. Techniques available include gloss and matte lamination, along with advanced options such as embossing, debossing, and foil stamping. These choices play a key role in improving the book’s tactile feel, lifespan, and overall market competitiveness.

Lamination

Lamination adds a protective layer to book covers, increasing durability and offering options in gloss or matte for visual appeal.

Foiling

Foiling applies metallic or pigmented foil to the cover, providing a premium finish and enhancing the book’s visual distinctiveness.

Embossing

Spot UV

Spot UV applies a UV-coated layer to specific areas of the cover, creating texture contrast and highlighting key design elements for visual interest.

Gilding

Color edge gilding adds metallic foil to the book’s edges, making them more durable and giving the book a unique look that matches the cover.

Varnishing

Varnishing involves applying a liquid coating to the cover to improve durability and add shine, with options for gloss, matte, or satin finishes. This can be done either in-line or off-line.

Materials

Paper Materials

We produce board books using either gray or white card stock, with rounded edges and laminated finishes. The card stock is covered with printed cover paper, featuring your story’s illustrations and text. Typically, board books have a “self-cover,” where the front, back, and spine are printed directly onto the outer boards, eliminating the need for a separate cover.

Given the emphasis on vibrant illustrations in most board books, we recommend printing on C1S paper, which is “coated one side” paper. This type of paper has a smooth, bright surface on the coated side, ideal for high-quality, full-color printing, while the uncoated side retains a natural, textured feel.

For children’s board books, we typically use 350gsm/16pt C1S paper. However, if a thinner option is preferred for cost reasons, 250gsm/12pt and 300gsm/14pt C1S paper are also suitable alternatives.

300gsm C1S Paper

350gsm C1S Paper

Types of Paperboard & Cardstock

- Whiteboard is crafted from bleached white fibers, offering superior quality and visual appeal. Although it is slightly more expensive than grayboard, most of our clients prefer whiteboard for their board books.

- Grayboard, on the other hand, features untreated compressed cardboard with gray fibers, covered by a white laminated exterior.

White Board

Greyboard

Cover Finishing Materials

When it comes to making a lasting impression with your book cover, several key finishing options are at your disposal. Lamination is often the go-to for adding both protection and a tactile quality, available in either gloss or matte finishes. If you’re aiming for a luxurious look, foiling can introduce metallic or colored highlights to your cover design.

Spot UV coating is another effective method for adding texture and drawing attention to specific cover elements. For those seeking a unique touch, edge gilding applies a metallic or colored foil to the book’s edges. And don’t overlook varnishing; available in gloss, matte, or satin, it provides that final layer of durability and sheen.

By carefully selecting the right finishing techniques, you can significantly enhance both the durability and aesthetic appeal of your book cover, making it a standout product.

Lamination Materials

Given the difference of glossiness and texture, lamination can be categorized as glossy lamination, matte lamination, scuff-free lamination and soft-touch lamination. The latter two options usually result in higher cost.

Foil Stamping Materials

Metallic Foil: The most common type, often available in gold, silver, and bronze, adds a shiny, metallic finish to the cover elements.

Pigment Foil: Unlike metallic, pigment foils offer a matte finish and are available in various colors, including white and black.

Holographic Foil: This foil creates a 3D effect, adding a futuristic and eye-catching element to the book cover.

Pearl Foil: Offering a pearlescent finish, this foil adds a subtle shine without being overly reflective.

Gloss Pigment Foil: This combines the color variety of pigment foils with the shiny finish of metallic foils.

Matte Metallic Foil: Provides the metallic look but with a subdued, matte finish.

Spot UV Materials

Gloss Varnish: This type provides a shiny, reflective finish, enhancing the vibrancy of colors on the book cover.

Matte Varnish: Offering a subdued, non-reflective finish, matte varnish is ideal for a more understated or elegant look.

Satin Varnish: Satin varnish strikes a balance between gloss and matte, offering a semi-gloss finish that’s not too shiny but still adds a touch of elegance.

UV Varnish: This is a special type of varnish cured with ultraviolet light, often used in Spot UV techniques to highlight specific areas of the cover.

Soft-Touch Varnish: This varnish gives the cover a soft, velvety feel, adding a tactile dimension to the book.

Accessories Materials

Want to give your board book that extra flair? Consider adding some stylish accessories. Ribbons make for elegant bookmarks and add a touch of class. Head and tail bands at the top and bottom of the spine not only look great but also offer added durability. And let’s not forget stickers; they’re a fun and easy way to showcase awards or special features. These little extras can make a big difference, turning an ordinary book into something special that readers will treasure.

When it comes to ribbons in board books, material matters. Most commonly made from satin, grosgrain, or even silk, these ribbons serve as built-in bookmarks that add a touch of luxury. Satin offers a smooth, glossy finish, while grosgrain provides a textured, ribbed feel. Silk, the epitome of elegance, takes the book’s aesthetic to the next level. Whichever material you choose, a ribbon bookmark adds both function and flair to your board book.

Ribbons

Stickers

When it comes to enhancing board books with stickers, the material choices are varied, each serving a specific purpose:

Paper Stickers: The most common type, usually 80gsm or 21 lb, ideal for general labeling or promotional use.

Vinyl Stickers: Known for their durability and water resistance, these are often used for outdoor or heavy-duty applications.

Polyester Stickers: These offer excellent heat and chemical resistance, making them suitable for specialized needs.

Foil Stickers: Made with metallic foil, these stickers add a luxurious, reflective quality to the book cover.

Clear Stickers: Made from transparent material, these are often used for a more subtle labeling effect.

Reusable Stickers: Created with special adhesives that allow for easy removal and reapplication.

Non-reusable Stickers: These use a stronger adhesive that ensures the sticker stays in place permanently.

About Huaxin

A family business founded in 1988 with three generations involved, Huaxin Printing has been devoting all its effort to print hardcover books with the highest possible quality.

Hua Xin has been certified with ISO 9001:2015 as well as the FSC (Forest Steward Council), and has been audited by 4-Pillar Sedex for social compliance (SMETA).

Let's Talk

If you intend to make some board books, or simply want to know more about us, feel free to send us a message.