Your beautiful new book has a problem. The pages are stiff and won’t lie flat. This simple oversight can ruin the entire reading experience and your reputation.

The grain direction, which is the alignment of paper fibers, dictates how a book’s pages lie, turn, and withstand stress. Using the correct direction ensures pages are flexible, lie flat when open, and the spine remains durable, directly impacting the book’s overall quality.

I’ve been in this business for 37 years, and I’ve seen how small details can make or break a project. One of the most critical, yet often overlooked, details is the paper grain direction. It’s a fundamental principle of printing that separates an amateur job from a professional one. Getting it right is about more than just aesthetics; it’s about the very structure and usability of the book you’re creating. Let’s dive into why this single factor is so important.

What is grain direction in printing?

You keep hearing the term "grain direction," but you are not sure what it means. Ignoring this can lead to production problems that are impossible to fix later.

Grain direction is the alignment of wood fibers in a sheet of paper. During manufacturing, these fibers line up in the direction the paper machine is running. This creates a "grain," similar to the grain in wood, which affects the paper’s properties.

To understand grain direction, you have to think about how paper is made. A slurry of wood pulp1 and water is poured onto a large, fast-moving screen. As the water drains away, the tiny wood fibers2 settle and tend to align themselves in the same direction the screen is traveling. This alignment is locked in as the paper is pressed and dried. This creates a distinct grain.

Identifying the Grain Direction

You don’t need a lab to figure To understand grain direction, you have to think about how paper is made. A slurry of wood pulp1 and water is poured onto a large, fast-moving screen. As the water drains away, the tiny wood fibers2 settle and tend to align themselves in the same direction the screen is traveling. This alignment is locked in as the paper is pressed and dried. This creates a distinct grain.

- The Fold Test: Take a rectangular sheet of paper and fold it in half one way, then unfold it and fold it the other way. One fold will be sharp and clean. The other will be slightly more ragged and resistant. The clean fold is with the grain.

- The Tear Test: Tearing the paper will also reveal its grain. A tear with the grain will be relatively straight and easy. A tear against the grain will be jagged and meet more resistance.

| Property | Long Grain | Short Grain |

|---|---|---|

| Bending | Bends easily along the short edge | Bends easily along the long edge |

| Tearing | Tears straighter along the long edge | Tears straighter along the short edge |

| Stiffness | Stiffer along the long edge | Stiffer along the short edge |

Why does grain direction matter?

You might think paper grain is a minor detail in a complex production process. But getting it wrong can ruin an entire print run and disappoint your client.

It matters because paper folds more easily and cleanly with the grain. For books, the grain must run parallel to the spine. This allows pages to turn easily, lie flat, and prevents the spine from warping or cracking. It is crucial for the book’s function.

The single most important rule in bookbinding is that the grain direction of the paper must run parallel to the spine. Think of the spine as the hinge of the book. For that hinge to work properly, the paper fibers need to bend along with it, not fight against it. When the grain is parallel to the spine, pages turn smoothly and lie flat when the book is open. This creates a pleasant and effortless reading experience.

The Impact on Different Binding Styles

This rule applies to all common binding methods, but the negative effects of getting it wrong are most obvious in certain types.

- Perfect Binding: With a wrong-grain book, the pages will have a constant "spring," wanting to snap shut. The added tension on the glued spine makes it much more likely to crack and fail over time.

- Hardcover Binding: The text block pages will buckle and warp, especially in humid conditions. They will not lie flat, and the book will feel stiff and uninviting to read.

- Saddle-Stitch: While less severe, the booklet will not hang or lie as flat. The pages will have a noticeable stiffness when turning.

I remember a client who insisted on an imposition plan1 to save a few cents per book. The plan forced the grain to run perpendicular to the spine. We advised against it, but they insisted. The final books looked terrible. The pages fought against the reader, and the spines were under so much stress they started to fail within weeks. It was a costly lesson in not sacrificing quality for minor savings. This is why at Huaxin Printing, our production planners always prioritize correct grain direction2 from the very start.

What happens if you fold paper against the grain?

You need to fold some paper, but what if you do it the wrong way? Folding against the grain creates a weak, ugly fold that looks unprofessional and fails structurally.

When you fold paper against the grain, the fibers resist and break instead of creasing smoothly. This results in a rough, cracked, and uneven fold line. In bookbinding, this means pages will be stiff, resist turning, and can cause the book to spring open.

Imagine trying to bend a small piece of wood. It bends easily along the grain but will crack and splinter if you try to bend it across the grain. Paper fibers act the same way. When you force a fold against the grain, you are essentially snapping thousands of tiny, interlocked fibers.

The Physics of a Bad Fold

This breakage is what causes the visible problems. The surface of the paper, especially if it’s a coated stock, will crack along the fold line. This looks terrible, particularly when there is heavy ink coverage, as the white paper stock shows through. Even if you use scoring before folding, it only helps a little. A score is a pressed indent to guide the fold, but it can’t change the fundamental direction of the fibers. Scoring against the grain can still lead to an inferior fold that won’t hold up over time.

This isn’t just about the interior pages. This principle applies to everything.

| Component | Folding WITH the Grain | Folding AGAINST the Grain |

|---|---|---|

| Book Pages | Lie flat, turn easily | Stiff, spring open, warp |

| Hardcovers | Boards remain flat | Boards can warp over time |

| Dust Jackets | Flaps fold cleanly | Folds may crack and look messy |

| Brochures | Sharp, professional folds | Bulky, cracked, uneven folds |

Every folded element of a book needs to be planned with grain direction in mind. A professional printer knows this and will never compromise.

How to choose grain direction?

You know grain direction is important, but how do you apply it in practice? Making the wrong choice during planning can be a very expensive mistake to fix later.

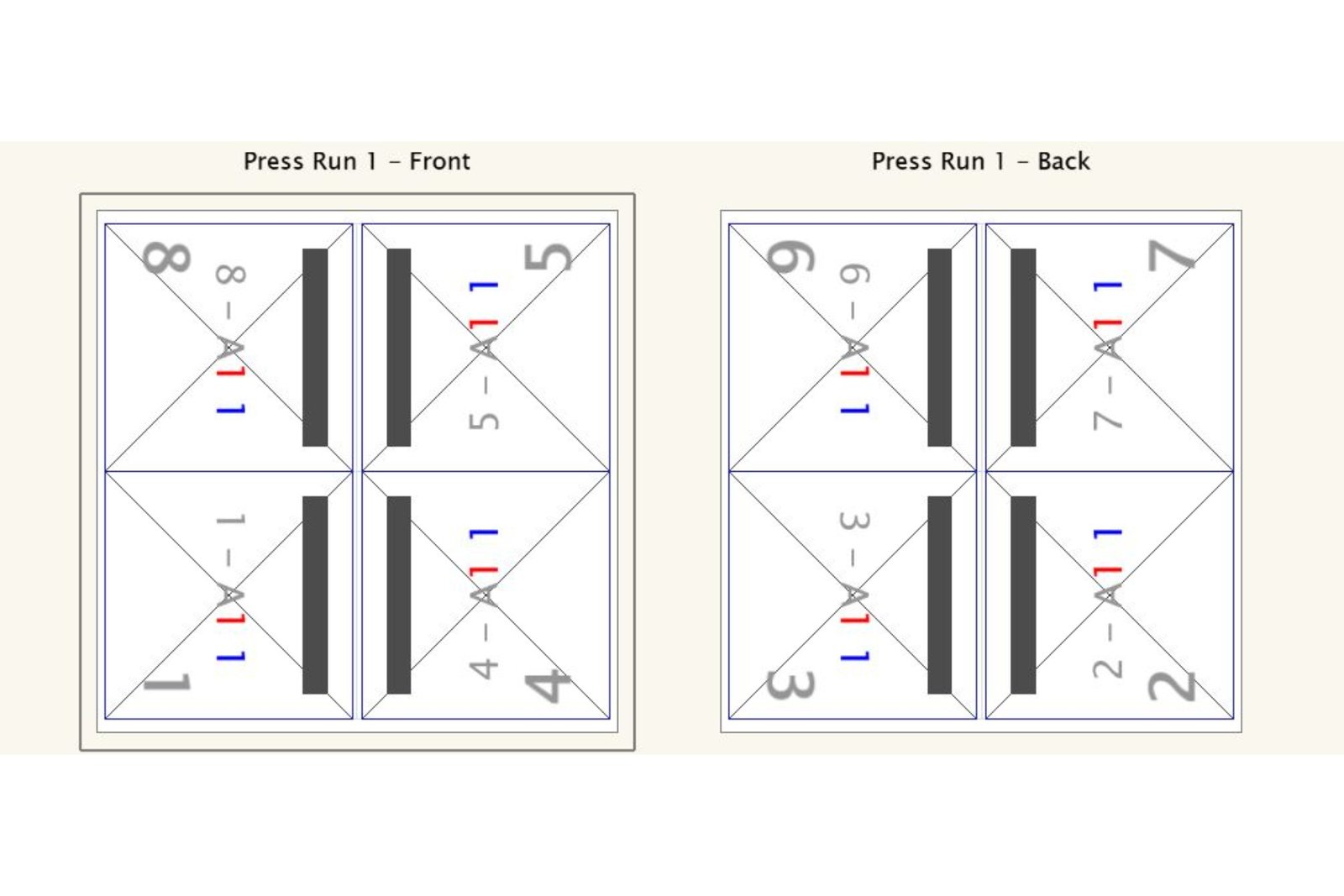

For books, always choose the grain direction that runs parallel to the binding edge. For a standard portrait book, you need "grain long" paper. This decision must be made early during production planning to ensure the right paper is ordered and used.

The choice is simple in theory but requires careful planning. The key is to match the paper’s grain to the book’s spine. For a standard book that is taller than it is wide (a portrait orientation), the spine runs along the long edge. Therefore, you need paper where the grain also runs along the long edge. This is called "long grain" paper. For a landscape book, you often need the opposite, "short grain" paper, where the grain runs parallel to the shorter side.

The False Economy of Ignoring Grain

This is where inexperienced planners can get into trouble. The goal of imposition is to fit as many book pages as possible onto a large parent sheet to minimize waste. Sometimes, turning the pages 90 degrees on the layout would fit one or two more pages on the sheet. This looks like a smart way to save money on paper.

However, this is a classic example of false economy. Let’s look at a simple case.

| Planning Method | Paper Usage | Book Quality | Final Cost |

|---|---|---|---|

| Prioritizing Grain | Slightly more paper waste | Excellent. Pages lie flat, spine is durable. | As quoted. Happy client. |

| Prioritizing Paper Saving | Minimal paper waste | Poor. Pages spring open, spine can crack. | High. Risk of reprint, unhappy client. |

Saving 3% on paper is meaningless if 100% of the books are unusable. A good printing partner like us at Huaxin Printing understands this balance. We use advanced planning software to create efficient layouts, but the rule of grain direction parallel to the spine is non-negotiable. It is a core principle of quality that we will never sacrifice to save a few pennies on paper.

Conclusion

Getting paper grain right is not a small detail; it is fundamental to book quality. It ensures durability and a great reading experience, protecting your brand and investment.