Choosing between offset and digital printing can feel overwhelming. Make the wrong choice, and you could overspend or compromise your book’s quality. Let’s make this decision simple for you.

The best printing method depends on your print run size. For quantities under 1,000 copies, digital printing is typically more cost-effective. For larger runs, especially over 2,000 copies, offset printing provides a lower per-unit cost and becomes the more economical choice.

But the final decision isn’t just about the number of copies. It’s about balancing cost, quality, speed, and the specific goals of your project. As someone who has spent over 38 years in this industry, I’ve helped countless clients navigate this choice. Let’s dive deeper to find the perfect fit for you, so you can print with confidence.

Which is better, offset or digital printing?

Feeling stuck trying to decide between two excellent printing options? Each has its own strengths, and picking the wrong one can hurt your budget and your book’s final look. Let’s compare them directly.

Neither method is universally "better." Digital printing is best for short runs, fast turnarounds, and projects requiring customization. Offset printing excels in superior quality, precise color consistency, and cost-effectiveness for large volume orders. The right choice depends on your project’s specific needs.

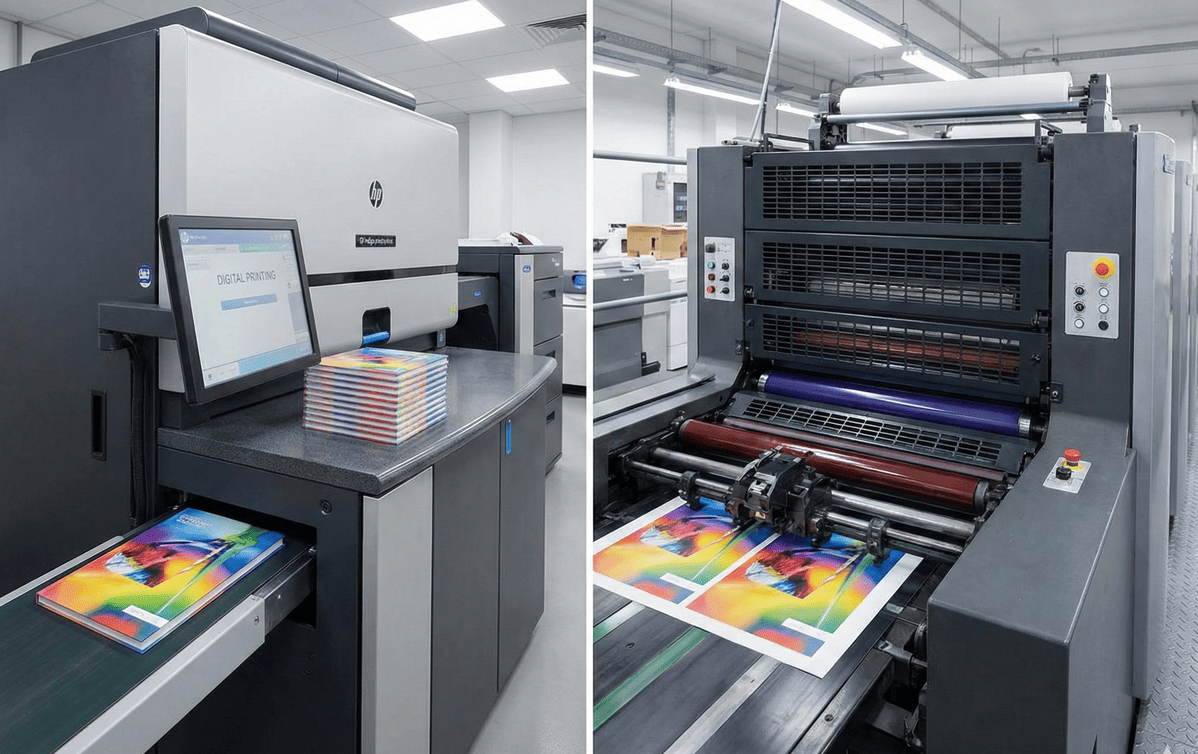

To truly understand which is better for you, we need to break down their core differences. I often explain it to my clients, like Stephanie, a print production director I’ve worked with for years, by looking at the technology itself. Digital printing works much like a high-end desktop printer, applying toner or ink directly onto the paper. This process is fast and requires minimal setup. In contrast, offset printing involves creating custom metal plates for your book’s pages. These plates transfer ink to a rubber blanket, which then prints onto the paper. This setup takes time and has a higher initial cost, but it produces incredible quality.

Here’s a simple table to help you see the differences at a glance:

| Feature | Digital Printing | Offset Printing |

|---|---|---|

| Best Quantity | Under 1,000 copies | Over 1,000-2,000 copies |

| Setup Cost | Very low to none | High (for creating plates) |

| Per-Unit Cost | Stays the same | Decreases as quantity increases |

| Turnaround Time | Fast (hours or days) | Slower (days or weeks) |

| Color Matching | Good (CMYK) | Excellent (CMYK + Pantone/Spot Colors) |

| Customization | Easy (Variable Data Printing) | Difficult and expensive |

Which is cheaper, digital or offset printing?

Are you worried about your printing budget? The price difference between digital and offset can be massive, and a misstep can drain your funds. Here’s a simple breakdown of the costs.

For short runs (typically under 1,000 copies), digital printing is cheaper because it has no plate or setup costs. For long runs (over 2,000 copies), offset printing is cheaper because the per-unit cost drops significantly as the quantity increases.

The key to understanding the cost is to look at how each method is priced. With digital printing, the cost per book is relatively static. Whether you print 100 or 1,000 copies, the price for each book stays about the same. This makes it incredibly predictable and affordable for smaller projects. I always recommend digital for authors printing advance reader copies (ARCs) or a limited first run. For a run of 500 copies, digital is almost always the most cost-effective path.

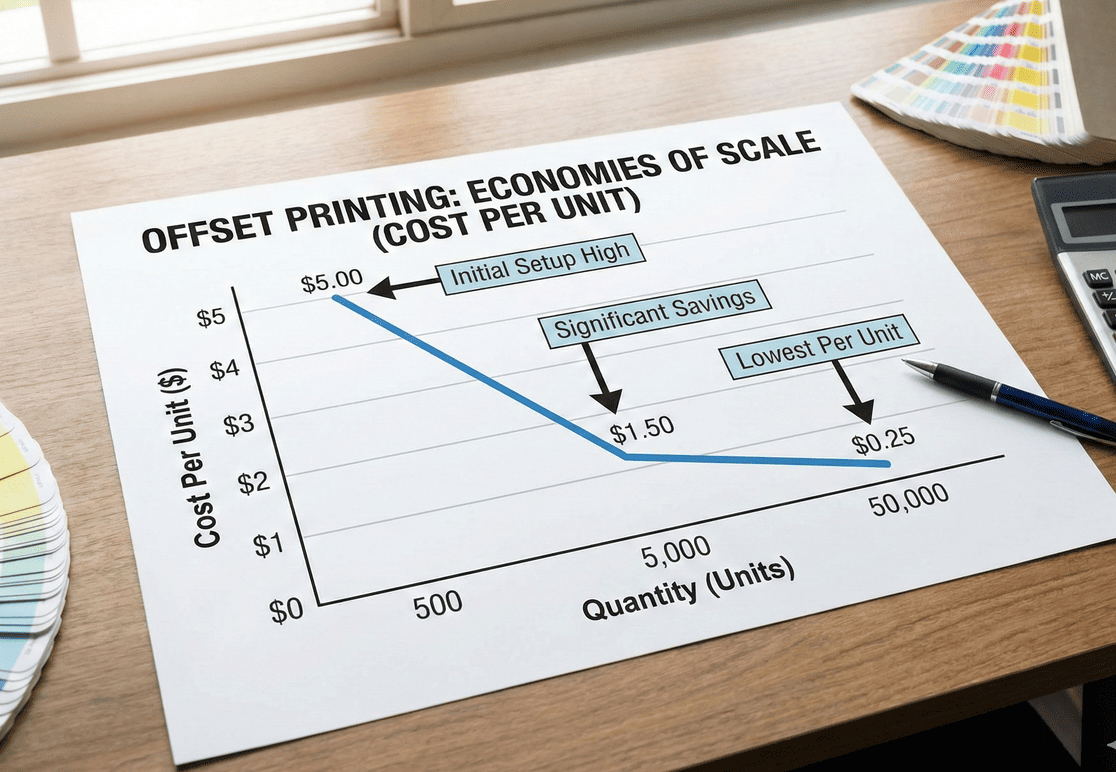

Offset printing works differently. There’s a significant upfront cost to create the plates and prepare the press. This "setup fee" makes small runs very expensive on a per-book basis. However, once the press is running, the cost to print each additional book is very low. This is why for a 5,000-copy run, offset printing offers a clear economic advantage. The high setup cost gets spread across thousands of books, making the per-unit price drop dramatically.

Let’s look at an example:

| Quantity | Digital Total Cost (at $5/book) | Offset Total Cost ($1500 setup + $2/book) | Cheaper Option |

|---|---|---|---|

| 500 | $2,500 | $2,500 | Tie / Digital |

| 1,000 | $5,000 | $3,500 | Offset |

| 5,000 | $25,000 | $11,500 | Offset |

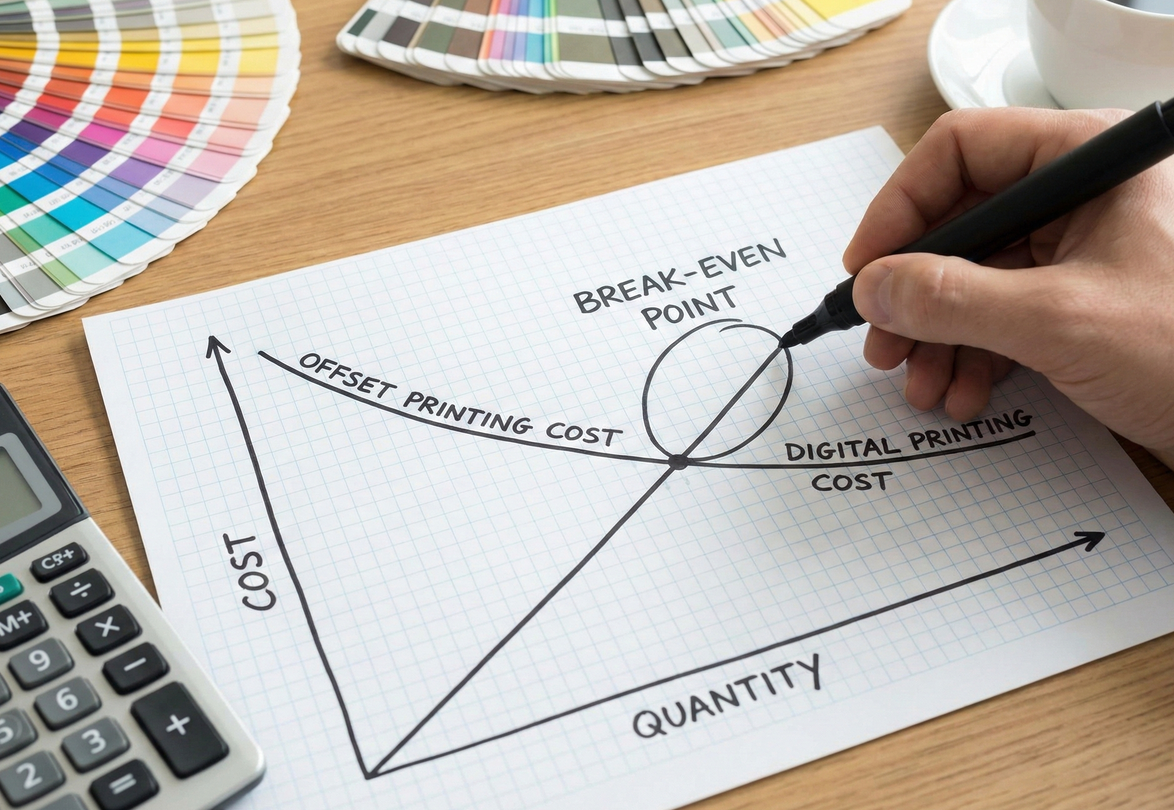

As you can see, the break-even point where costs converge happens around the 500-1,000 copy mark.

Why is digital printing cheaper for small runs and offset for large runs?

Does the pricing logic for printing seem a little strange? It’s understandably confusing why one method is cheap for small jobs and expensive for big ones, and vice versa. Let’s demystify the economics.

Digital printing is cheaper for small runs because it skips the expensive and time-consuming setup process of creating printing plates. Offset printing requires this costly setup, but once it’s done, the per-copy cost becomes very low, making it cheaper for large quantities.

The answer lies in fixed versus variable costs. Think of it like this: offset printing has a high fixed cost. This is the setup fee—the money you spend on plates and getting the press ready before the first book is even printed. This cost is the same whether you print 500 or 50,000 books. However, its variable cost—the price of ink and paper for each individual book—is very low.

Digital printing is the opposite. It has almost zero fixed cost. We can take a file and start printing almost immediately. But its variable cost per book is higher than offset’s. I often use an analogy with clients: digital printing is like baking cookies in your home oven. You can make a dozen easily with no real setup. Offset printing is like firing up an industrial bakery. It takes time and money to get all the equipment running, but once you do, you can produce thousands of cookies for just pennies each. This principle, known as economies of scale, is why offset becomes so much more affordable as your print run grows.

How do you calculate the break-even point for a printing project?

Do you want to know the exact number of copies where offset becomes cheaper than digital? Guessing can lead to overspending, so you need a reliable way to find that sweet spot. Here’s a simple formula.

To find the break-even point, divide the total setup cost of offset printing by the difference in the per-unit cost between digital and offset. The formula is: Break-Even Point = Offset Setup Cost / (Digital Cost Per Unit – Offset Cost Per Unit).

This calculation gives you the exact quantity where the total cost for both methods becomes equal. Printing any more than that number means offset will be the cheaper choice. Let’s walk through a practical example. Say you get a quote from a printer like us at Huaxin Printing, and the numbers look like this:

Printing Cost Breakdown

- Offset Printing Setup Cost: $1,500 (this is your fixed cost)

- Offset Cost Per Book: $2.00 (this is your variable cost)

- Digital Cost Per Book: $5.00 (variable cost, with no fixed cost)

Now, let’s plug these numbers into the formula:

- Difference in Per-Unit Cost: $5.00 (Digital) – $2.00 (Offset) = $3.00

- Break-Even Point: $1,500 (Offset Setup Cost) / $3.00 (Difference) = 500 copies

In this scenario, if you plan to print more than 500 copies, offset printing will save you money. These numbers are just for illustration; in the real world, the break-even point often falls between 1,000 and 2,000 copies. The best way to be sure is to ask your printer for quotes for both methods at different quantities.

What about color quality and consistency?

Is cost the only thing that really matters in this decision? Choosing based on price alone can lead to colors that don’t match your brand or look inconsistent across your print run. Let’s look at color.

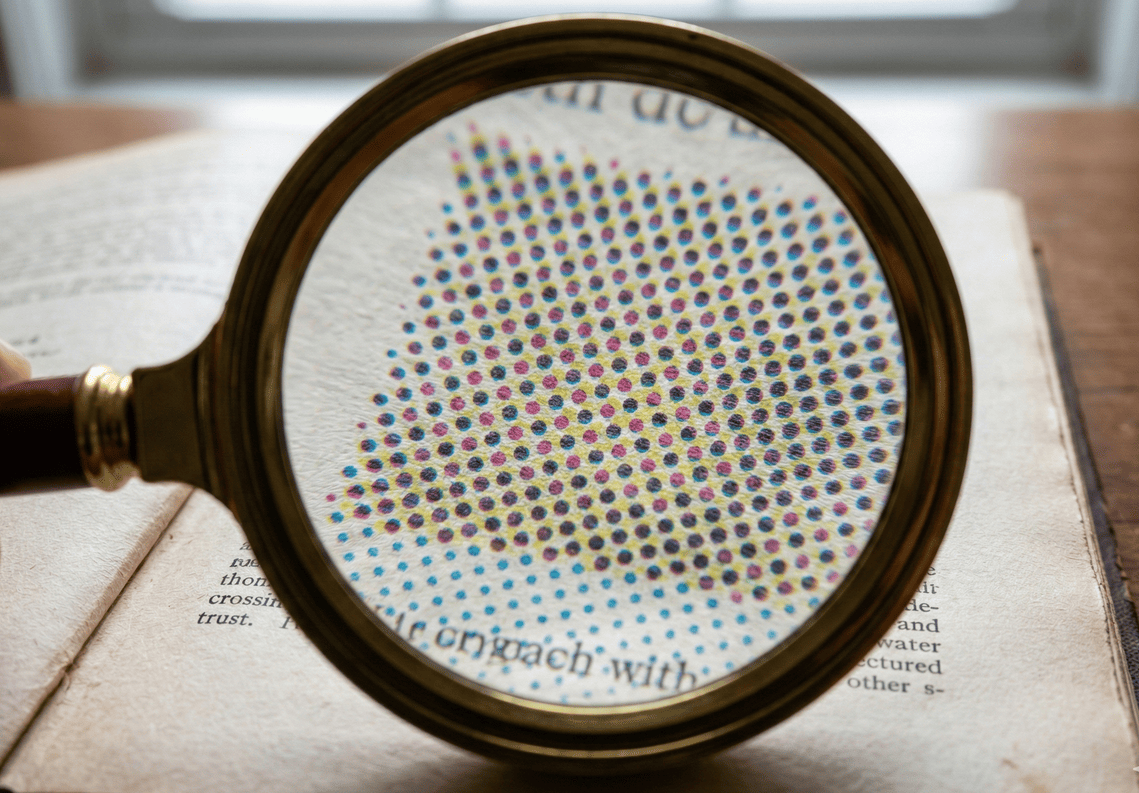

Offset printing offers superior color quality and consistency, especially for large runs and brand-specific Pantone colors1, because it uses liquid ink and dedicated plates. Digital printing quality is excellent but can have slight variations, making it less ideal for projects where exact color is critical.

After 38 years surrounded by paper and ink, I can tell you that the difference is in the details. Offset printing uses liquid inks (either in the standard CMYK combination or custom-mixed Pantone colors). These inks absorb into the paper, creating rich, deep, and incredibly precise colors. When a client like Stephanie needs the specific blue in her company’s logo to be perfect on every one of the 5,000 book covers she’s ordering, offset is the only way I can guarantee that consistency. Every single cover will be an identical match.

Digital printing, which uses toner or droplets of ink, has come a long way. The quality is fantastic for most applications, and the color is vibrant. However, you can sometimes see very slight variations from the first copy to the last. For a novel or a manual, this is rarely an issue. But for a high-end photography book, an art catalog, or brand-sensitive marketing materials, those minor shifts can matter. If your project demands the absolute highest fidelity and unwavering consistency, offset printing remains the industry’s gold standard.

Conclusion

The choice between offset and digital depends on your quantity, budget, and quality needs. Use the break-even point as your financial guide, but always consider your project’s unique creative goals.

-

Learn about Pantone colors and their role in achieving precise color matching in printing projects. ↩