Proudly Served

A softcover book, also known as a paperback, features a flexible cover made from paper, typically bound using adhesive or stitching methods. In contrast to hardcovers, the softcover’s lighter and more flexible binding enhances portability and ease of use. This makes softcover books an ideal choice for bulk publications, such as manuals, educational resources, and promotional materials.

How A Softcover Book Is Made?

The production of a softcover book involves several stages: prepress, printing, folding, thread sewing (or perfect binding), and paperback binding. This intricate process demands both cutting-edge machinery and extensive expertise.

With 36 years of industry experience, Huaxin Printing delivers a comprehensive in-house manufacturing solution, ensuring no need for outsourcing. Our expert color management guarantees that your products consistently meet the highest quality standards.

Prepress

Elevate your print projects with advanced prepress experience and compliance with ISO 12647-7 color management standard.

Printing

Fully automated printing presses with the speed of up to 18,000 sheets per hour. CIP-3 ink management and experienced press operators.

Folding

Swift adjustment of any trim sizes from 8-page per signature to 64-page per sheet. Up to 700,000 sheets per day.

Thread Sewing

Fully automated sewing machines can sewn up to 600,000 sheets per day. Semi-automatic oversized sewing can be accomplished as well.

Paperback Binding

Fully automated paperback binding machine with 25 sets of pagination. Up to 95,000 pieces per day.

Packaing

Experienced packing staffs ensure your books be delivered safely to your required destination, across the globe.

Our Works

Trade Book

Comic Book

Catalog

Binding for Softcover Books

Types of Softcover Binding

Section Sewn

“Section sewn” refers to the technique of using thread to stitch together small groups of pages, called ‘signatures,’ in paperback books. This method ensures a durable, lay-flat design, making it ideal for books that are frequently handled.

Perfect Binding

“Perfect binding” involves gluing the pages of a paperback book directly to the spine. This method provides a sleek and cost-effective option, commonly used for novels and catalogs. It cost less, but it will be less secured than section sewn option if the book has a higher number of pages.

PUR Binding

“PUR binding” employs polyurethane-reactive adhesive to attach pages to the spine of a paperback. Renowned for its exceptional durability, it is the preferred choice for books that undergo heavy use or are printed on coated paper.

Flap

A “flap” in a paperback is an extension of the cover that folds inward, providing extra space for design elements, author bios, or summaries. It can also function as a bookmark, adding a premium feature to the book.

Book Sizes

Searching for the ideal format for your next paperback project? Whether you prefer portrait or landscape, we provide a variety of sizes to suit your genre, audience, and content. Here’s a quick guide to popular sizes for different genres to help you get started.

At Huaxin Printing, we provide both custom sizes tailored to your specific needs and standard sizes that adhere to industry standards. Knowing these options is essential for making well-informed decisions, ensuring your print project is both visually appealing and functionally practical.

| US Market | Europe & ANZ Market |

|---|---|

| Book Sizes | Book Sizes |

| 8.5″ x 11″/ 6″ x 9″/ 8″ x 10″/ 5.5″ x 8.5″ | 210 mm x 297 mm/ 152 mm x 230 mm/ 148 mm x 210 mm |

| Catalog, Magazine and Booklet Sizes | Catalog, Magazine and Booklet Sizes |

| 8.5″ x 11″/ 5.5″ x 8.5″ | 210 mm x 297 mm/ 148 mm x 210 mm |

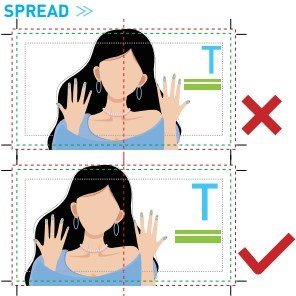

Designing Tips

For softcover books, captivating artwork and accurate typography are essential. Whether you’re handling the design yourself or working with a professional, getting the print-ready files right is crucial. Focus on bleed zones, safety margins, and trim lines, and ensure your images are high-resolution and in the correct color space to meet your design objectives.

Here are some key tips for file preparation to ensure the best printing results.

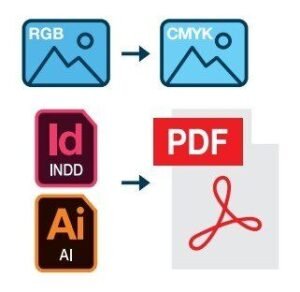

For the best printing results, it’s recommended to save your files in PDF format with vector graphics. We suggest using Adobe Illustrator or Adobe InDesign for designing softcover books. These tools also allow you to convert your color space from RGB to CMYK, which is essential for offset printing.

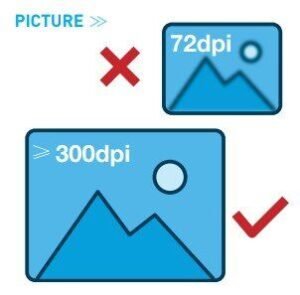

If vector files aren’t feasible, such as when working with bitmaps from Photoshop, it’s essential to maintain a resolution of at least 300 DPI. Unlike vectors, raster images must be high-resolution to prevent quality degradation during resizing.

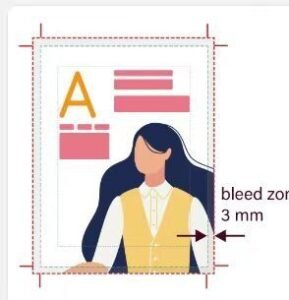

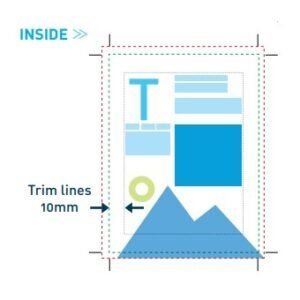

Within the 3 mm bleed zone, it’s vital to mark the trim lines that define the final size of the page. Make sure that all key elements are placed at least 10 mm away from these trim lines.

In your specified bleed zone, it’s important to highlight the trim lines that determine the final size of the page. To achieve the best results, keep key elements at least 10 mm away from these lines.

When a photo or artwork spans a two-page spread, be sure that important elements, such as facial features or key details, are not positioned on the central fold.

Maintain consistency in all formatting elements throughout the document, including fonts, font sizes, drop caps, section dividers, page numbers, margins, chapter titles, and page breaks.

Pricing

| Page Numbers | 500 copies | 1,000 copies | 2,000 copies | 5,000 copies |

|---|---|---|---|---|

| 80 pages | USD 1.85 | USD 1.19 | USD 0.89 | USD 0.72 |

| 128 pages | USD 2.76 | USD 1.79 | USD 1.36 | USD 1.11 |

| 208 pages | USD 4.30 | USD 2.79 | USD 2.12 | USD 1.75 |

| 256 pages | USD 5.22 | USD 3.41 | USD 2.59 | USD 2.13 |

Remarks:

- All prices above are the unit prices corresponding to the number of text pages and print-runs;

- All prices are EXW only and does not include any logistics cost;

- All prices are based on the trim size of 8.5″ * 11″ (216 * 280mm);

- Cover 250gsm/91 lb coated art card with matte lamination;

- Text pages 105gsm/ 71lb coated matte art paper;

- Cover and text pages all color printed;

- Packed no more than 18kg/carton, no shrinkwrapping

Finishing

In the book manufacturing process, cover finishing plays a crucial role in enhancing both the visual appeal and durability of the final product. Techniques such as gloss and matte lamination, along with advanced methods like embossing, debossing, and foil stamping, are key in improving the book’s tactile quality, longevity, and market competitiveness.

Lamination

Lamination adds a protective layer to book covers, increasing durability and offering options in gloss or matte for visual appeal.

Foiling

Foiling applies metallic or pigmented foil to the cover, providing a premium finish and enhancing the book’s visual distinctiveness.

Embossing

Spot UV

Spot UV applies a UV-coated layer to specific areas of the cover, creating texture contrast and highlighting key design elements for visual interest.

Gilding

Color edge gilding adds metallic foil to the book’s edges, making them more durable and giving the book a unique look that matches the cover.

Varnishing

Varnishing involves applying a liquid coating to the cover to improve durability and add shine, with options for gloss, matte, or satin finishes. This can be done either in-line or off-line.

Materials

Paper Materials

For the text pages of softcover books, paper quality plays a vital role in both readability and the overall user experience. Uncoated, matte paper is often chosen for its readability and minimal glare. If your text pages include color printing, coated matte art paper may be a better option. Consider the paper’s weight and opacity as well, especially for books with a high text-to-image ratio, as this can influence ink bleed-through and page transparency.

For the cover, a sturdier, coated card stock paper, such as C1S, is typically used. This not only enhances the visual appeal of the cover art but also increases durability. The choice of finish—matte or glossy—further affects the tactile experience and overall aesthetic quality.

Glossy Art Paper

Matte Art Paper

Uncoated Woodfree Paper

Paper Options for Softcover Books

While there are many paper options available for printing your books, certain types are more commonly used for softcover book printing and binding. If you need your books printed quickly and want to use widely accepted paper types, consider the options listed below, which are more readily available in the market.

Text Paper

- 80gsm/54lb coated

- 105gsm/71lb coated

- 128gsm/86lb coated

- 157gsm/106lb coated

- 80gsm/54lb uncoated

- 100gsm/68 lb uncoated

Cover Paper

- 250gsm / 92lb C1S Cover

- 300gsm / 111lb C1S Cover

Cover Finishing Materials

To create a memorable book cover, several finishing options can be utilized. Lamination is a popular choice for adding protection and a tactile quality, available in gloss or matte finishes. For a more luxurious appearance, foiling can add metallic or colored highlights to your cover design.

Spot UV coating is an excellent option for adding texture and emphasizing specific elements on the cover. For a unique touch, edge gilding applies metallic or colored foil to the book’s edges. Varnishing, available in gloss, matte, or satin, provides an additional layer of durability and sheen.

By selecting the appropriate finishing techniques, you can greatly enhance both the durability and visual appeal of your book cover, making it truly stand out.

Lamination Materials

Lamination can be categorized by its glossiness and texture into four types: glossy lamination, matte lamination, scuff-free lamination, and soft-touch lamination. The latter two options generally come with a higher cost.

Foil Stamping Materials

Metallic Foil: The most common type, often available in gold, silver, and bronze, adds a shiny, metallic finish to the cover elements.

Pigment Foil: Unlike metallic, pigment foils offer a matte finish and are available in various colors, including white and black.

Holographic Foil: This foil creates a 3D effect, adding a futuristic and eye-catching element to the book cover.

Pearl Foil: Offering a pearlescent finish, this foil adds a subtle shine without being overly reflective.

Gloss Pigment Foil: This combines the color variety of pigment foils with the shiny finish of metallic foils.

Matte Metallic Foil: Provides the metallic look but with a subdued, matte finish.

Spot UV Materials

Gloss Varnish: This type provides a shiny, reflective finish, enhancing the vibrancy of colors on the book cover.

Matte Varnish: Offering a subdued, non-reflective finish, matte varnish is ideal for a more understated or elegant look.

Satin Varnish: Satin varnish strikes a balance between gloss and matte, offering a semi-gloss finish that’s not too shiny but still adds a touch of elegance.

UV Varnish: This is a special type of varnish cured with ultraviolet light, often used in Spot UV techniques to highlight specific areas of the cover.

Soft-Touch Varnish: This varnish gives the cover a soft, velvety feel, adding a tactile dimension to the book.

Accessories Materials

Looking to add an extra touch of sophistication to your softcover book? Consider incorporating some stylish enhancements. Ribbons can serve as elegant bookmarks, adding a touch of refinement. Stickers are another option, perfect for highlighting awards or special features. These small additions can elevate your book, transforming it from ordinary to something truly memorable for readers.

When it comes to ribbons in hardcover books, material matters. Most commonly made from satin, grosgrain, or even silk, these ribbons serve as built-in bookmarks that add a touch of luxury. Satin offers a smooth, glossy finish, while grosgrain provides a textured, ribbed feel. Silk, the epitome of elegance, takes the book’s aesthetic to the next level. Whichever material you choose, a ribbon bookmark adds both function and flair to your hardcover book.

Ribbons

Stickers

When it comes to enhancing softcover books with stickers, the material choices are varied, each serving a specific purpose:

Paper Stickers: The most common type, usually 80gsm or 21 lb, ideal for general labeling or promotional use.

Vinyl Stickers: Known for their durability and water resistance, these are often used for outdoor or heavy-duty applications.

Polyester Stickers: These offer excellent heat and chemical resistance, making them suitable for specialized needs.

Foil Stickers: Made with metallic foil, these stickers add a luxurious, reflective quality to the book cover.

Clear Stickers: Made from transparent material, these are often used for a more subtle labeling effect.

Reusable Stickers: Created with special adhesives that allow for easy removal and reapplication.

Non-reusable Stickers: These use a stronger adhesive that ensures the sticker stays in place permanently.

About Huaxin

A family business founded in 1988 with three generations involved, Huaxin Printing has been devoting all its effort to print hardcover books with the highest possible quality.

Hua Xin has been certified with ISO 9001:2015 as well as the FSC (Forest Steward Council), and has been audited by 4-Pillar Sedex for social compliance (SMETA).

Let's Talk

If you intend to make some softcover books, or simply want to know more about us, feel free to send us a message.