Book Printing

Proudly Served

Book printing involves advanced technologies like offset and web printing, ensuring high-resolution reproduction of text and images. Key processes include CTP (Computer-to-Plate) output, color management, and quality inspections, all of which guarantee precision, efficiency, and consistency in large-scale book production.

The Workflow of Printing

The typical procedure for book printing involves steps such as paper selection, reprographic, file proofing, CTP output, press printing and quality inspection. Such a complex process requires advanced machinery and seasoned expertise.

With 36 years of industry experience, Huaxin Printing provides a comprehensive in-house printing solution, with sophisticated skills and system for color consistency management. Our specialized color management guarantees that your product meets the highest standards.

Paper Selection

The selection of paper will largely influence the profile applied to the files. So it is very important to confirm the paper at the first step.

Reprographic

Reprographics ensures precise reproduction of images and text in book printing, optimizing color, layout, and resolution for print outputs.

File Proofing

File proofing verifies layout, colors, and content accuracy before book printing, ensuring the final print matches the desired design and quality.

CTP Output

CTP (Computer-to-Plate) output transfers digital files directly onto printing plates, ensuring accurate, high-resolution images and text for efficient and precise book printing.

Press Printing

Press printing transfers ink onto paper through plates, delivering high-quality, consistent prints for large-volume book production with accurate color and detail reproduction.

Quality Inspection

Quality inspection of printed sheets ensures alignment, color accuracy, and consistency for each project to meet required standards before proceeding with binding and final production.

Our Printing Works

Why Paper Matters for Printing?

Impact of Paper on Color: Different paper stocks (coated, uncoated, matte, glossy) affect how ink absorbs and how colors appear. Glossy papers reflect more light, making colors more vibrant, while uncoated papers may dull colors.

Paper Whiteness: Whiter paper provides more contrast, making colors appear brighter, whereas off-white or cream-colored papers can give the book a warmer tone but might impact the color vibrancy.

When printing on coated paper, color profiles are adjusted to enhance vibrancy and sharpness, as the coating prevents ink from being absorbed deeply, resulting in more saturated colors and finer details. Coated papers often require profiles with higher ink limits to fully leverage the smooth, reflective surface. FOGRA 51 is more recommended for coated paper.

For uncoated paper, color profiles must account for greater ink absorption, which can dull colors and reduce contrast. Here, profiles are optimized with lower ink limits and adjustments in tonal values to maintain clarity, while compensating for the paper’s more porous and matte surface. This ensures accurate color reproduction and avoids excessive ink spread. FOGRA 52 is more recommended for uncoated paper.

Coated Glossy Art

Coated Matte Art

Uncoated Woodfree

CMYK vs RGB?

What you see on your computer screen is NOT always what you get from the printer when it comes to printing your design files.

Color Models:

- RGB (Red, Green, Blue): Designed for digital screens, combining light to create colors. It offers a wide color gamut, resulting in vibrant images for electronic displays.

- CMYK (Cyan, Magenta, Yellow, Black): Used in printing, where ink is applied to paper. CMYK works by subtractive mixing, where layers of ink absorb light to produce colors.

Difference in Color Gamut:

- RGB has a broader color range, making it ideal for screens but unsuitable for print.

- CMYK has a narrower color gamut, but it’s tailored for physical materials, ensuring printed colors match intended designs as closely as possible.

What to do with CMYK printing?

Always Use CMYK for Printing. Sending an RGB file may result in inaccurate colors, as RGB hues cannot be replicated with ink.

- For all your images acquired and processed with digital devices, make sure that RGB should be converted into CMYK. Converting files from RGB to CMYK ensures that colors appear as intended during the printing process, avoiding unexpected shifts in tones, saturation, or brightness.

Avoiding Color Shifts: Without proper conversion, vibrant RGB colors can appear dull or muted in print. Converting to CMYK before printing guarantees more accurate color matching.

Proofing Before Printing

Proofing is the process of checking a print job for errors before it is printed.

This step is essential because it allows you to catch and fix any mistakes before they become expensive and time-consuming printing problems. You can be confident that your printed piece will be accurate and perfect by proofing your job.

Below are some major options of proofing:

A dummy is a set of blank pages, folded and numbered, used to assess a book’s layout and page structure before printing. It is an unprinted sample created with the same paper stock and binding method as the final product. With a dummy, you can check aspects such as the inner paper, binding style, cover finish, paper type, thickness, and book size. It provides a realistic preview of the final product’s look and feel without any printing involved.

Also called as soft proofing. It refers to reviewing a precise digital representation of a file on a monitor before printing. The most straightforward approach is confirming content through PDF files. This digital proofing method, often available as an online preview, can act as a contract between the supplier and buyer, replacing traditional hard copy proofs. If properly managed, soft proofing systems can outperform traditional methods in terms of speed, distribution, cost-effectiveness, consistency, and efficiency. Tools like Kodak InCite and Ziflow are commonly used for effective soft proofing.

Plotter proofs, also called injekt proofs or ozalids proofs, are a cost-effective option for checking content, layout, and pagination. They allow you to ensure everything is correctly placed and that the overall product flows as intended, as they can be transformed into booklets or brochures.

While inkjet proofs can be trimmed or bound to simulate the final appearance, they do not always reveal issues like color accuracy.

Wet proofs are another sort of proofing. These are taken right from the press at the commencement of a production run. These proofs are thoroughly examined for clarity and color accuracy as part of the manufacturing process. Bleed, and crop marks are included on all proofs. Wet proofs are the only ones that are printed on the actual paper that will be used for the print run. Given that such color proofs are printed on actual offset presses, the cost of wet proofing is much higher, and thus being used much less frequently.

Designing Tips

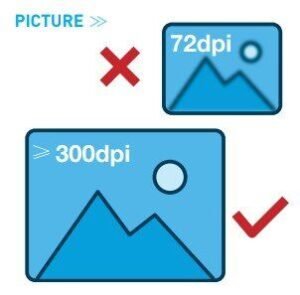

While each binding type of books may have some specific requirements for artwork designs, there are something in common, such as the image resolution and bleeding lines

Here are key tips for file preparation to achieve optimal printing results.

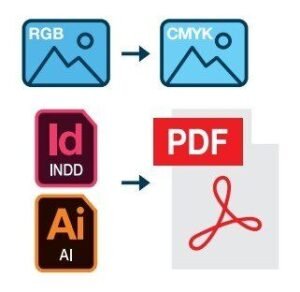

For optimal printing results, it’s recommended to save your files in PDF format as vectors. We advise using Adobe Illustrator or Adobe InDesign for designing flexibound books. These platforms also allow for the necessary conversion of color space from RGB to CMYK, which is essential for offset printing.

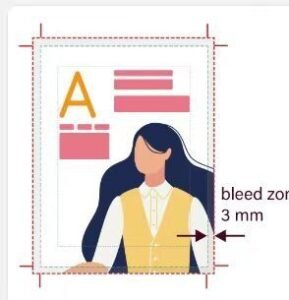

Within the required 3 mm bleed zone, it’s important to indicate trim lines that define the final dimensions of the finished page. Make sure that key elements on your page are placed at least 10 mm away from these trim lines.

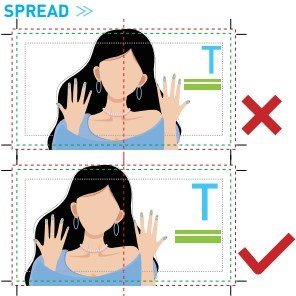

When a photo or artwork spans a two-page spread, make sure that critical elements, such as facial features or key details, do not fall on the central fold.

Ensure consistency in all formatting elements throughout the document, including fonts, font sizes, drop caps, section dividers, page numbers, margins, chapter titles, and page breaks.

What Does Signature Mean for Printing?

What Is Signature & Imposition?

A print signature in book printing refers to a group of pages printed on a single large sheet of paper. Instead of printing pages individually, multiple pages are arranged and printed together on both sides of the sheet.

Books are NOT printed page by page, instead, multiple pages are arranged in one large sheet and being printed together. Such process is called imposition. In printing, imposition is the process of arranging pages or images on a sheet to ensure they appear in the correct order after folding, trimming, and binding

Page Signature Layout

Depending on the book’s designed trim size, a signature can contain 8, 16, 24, 32, or 64 pages, with each side of the sheet holding half of the total page count. Once the sheets are printed, they are folded according to the trim size, creating a booklet-like structure. These signatures are later bound together to form the complete book.

16 Pages per Signature

32 Pages per Signature

Common Sizes for Imposition

Below are some commonly used trim sizes with their corresponding to the imposition layout

| Imposition Layout | Size 1 | Size 2 | Size 3 |

|---|---|---|---|

| 8 Pages Per Signature | 285*420mm | 260*370mm | 240*340mm |

| 16 Pages Per Signature | 210*285mm | 185*260mm | 170*240mm |

| 32 Pages Per Signature | 145*210mm | 130*185mm | 120*170mm |

Printing Machines

Book printing involves various printing technologies that cater to different needs in terms of quality, volume, and speed.

The three main types of presses used in book printing are digital, sheet fed, and web printing.

Digital Printing

Digital printing machines use digital files to directly print on materials, offering fast turnaround and minimal setup. Popular brands include HP Indigo, Xerox, and Canon. They’re ideal for short-run orders, on-demand printing, and personalized products due to their flexibility and cost-efficiency for smaller quantities.

Sheet Fed Printing

Sheet fed printing machines transfer ink from a plate to a rubber blanket, then onto paper, ensuring high-quality and consistent prints. Popular brands include Heidelberg, Komori, and Manroland. They are ideal for large-volume orders, like books, calendars, and packaging, due to their efficiency and precision.

Web Printing

Web printing machines use large rolls of paper that pass through the press for high-speed, continuous printing. They are ideal for large-volume jobs like newspapers, magazines, and catalogs. Popular brands include Heidelberg, Komori, and Manroland. These machines are best for long-run, cost-efficient orders.

Color Management

Color Management

Color management in book printing ensures that colors appear consistently from design to final print. It involves using ICC profiles, converting RGB to CMYK, and calibrating equipment to maintain accurate color reproduction. Effective color management accounts for factors like paper type, ink limits, and print methods to achieve consistent, high-quality results. Regular proofing and real-time color monitoring during printing help avoid color shifts, ensuring the final product matches the original design.

Color Profiles

Color Profiles are predefined sets of data that help ensure accurate color reproduction between devices like monitors, printers, and presses.

In book printing, color profiles play a crucial role in ensuring color consistency across different stages of the printing process. A color profile defines how colors should appear on various devices, such as monitors, printers, and presses. By using standardized ICC profiles, the colors in a digital file are accurately translated into the physical print, regardless of equipment variations.

This ensures that the colors you see on screen or in proofs match the final printed product. The right color profile also takes into account factors like paper type and ink limits, minimizing color shifts and maintaining consistency, especially in large print runs. Below are some tips about how to better manage the color profiles in order to achieve the color consistency. You may talk to your printers and see how well they are prepared for that.

- Obtain Profiles from Your Printer: Always ask your printer for their recommended ICC color profiles, which are tailored to their specific press, ink, and paper setup. Using the correct profile ensures that your design will be accurately translated during the print process.

- Install Profiles on Design Software: Load the provided ICC profiles into your design software (e.g., Adobe InDesign, Photoshop) and apply them to your project. This ensures your digital file is aligned with how the colors will print.

- Regularly Calibrate Your Display: Use a hardware calibration tool to calibrate your monitor, ensuring that the colors on your screen match those in the final print when using the correct color profile. Even the best color profile won’t work properly if your monitor is not displaying accurate colors.

- Set Your Design Software to Match: Ensure your design software (e.g., Adobe Creative Suite) is set to use the ICC profile for accurate color display while designing.

- Convert Early in the Design Process: Ensure you convert your file from RGB to CMYK at the beginning or early stages of the design process using the appropriate ICC profile. This helps to minimize unexpected color shifts and ensures that you’re working with a print-ready palette.

- Preview the CMYK Output: Use the soft proofing feature in your design software to simulate how the colors will look when printed in CMYK with the specific profile applied.

- Request Hard Proofs Using the Profile: Before committing to a full print run, request a hard proof that uses the exact color profile and paper for your project. This will give you a tangible view of how colors will look and allow adjustments before mass production.

- Compare to Digital Proofs: Compare hard proofs with digital proofs to spot any major color discrepancies and discuss necessary adjustments with your printer if the print result is significantly off.

- Coordinate Proofing and Profiles: Maintain close communication with your printer to ensure they’re using the same profile that you applied to your design. Ensure that no unexpected changes occur in the printing process.

- Discuss Color Variability for Long Runs: Talk with your printer about color consistency across long print runs and how they will maintain it using your chosen profile. Regular press calibration and ink level monitoring are essential.

Color Variation

In book printing, color variation can arise due to multiple factors, making it essential to manage expectations when it comes to achieving color consistency, especially when comparing the final print to proofing samples.

Lamination

Gloss lamination tends to enhance colors by making them appear more vibrant and saturated.

Matte lamination dulls the colors slightly and reduces contrast. Colors may appear less vibrant and softer compared to the proof.

Paper

Coated papers reflect light and tend to produce sharper images and more vibrant colors.

Uncoated papers absorb more ink and can result in colors appearing more muted and softer compared to the proof.

Printing Quality Inspection

Printing Quality

Quality inspection of printed sheets for book printing involves three essential areas. First, color consistency ensures uniform reproduction across all sheets, comparing them to the approved proof to detect any shifts in color. Tools like spectrophotometers are used to measure color accuracy. Second, registration accuracy checks that color plates are properly aligned, preventing blurring or ghosting, especially in multi-color prints. Third, ink density and coverage ensures consistent ink levels across sheets, avoiding issues like uneven coverage or over-inking, which can cause smudging or setoff. These measures guarantee the final print quality meets professional standards.

Color Consistency

- Check for Uniform Color Reproduction: Ensure that colors remain consistent across all sheets in the print run. This involves comparing the first and last sheets to spot any deviations in color density or shifts. Tools like spectrophotometers can be used to measure color accuracy against the reference proof or standard.

- Verify Color Match to Proof: Inspect the printed sheets against the approved proof (digital or hard proof) to confirm that the colors match exactly. Any noticeable variations should be addressed before continuing the print run.

Registration Accuracy

- Ensure Proper Alignment of Colors: In multi-color printing, especially with CMYK, check that the color plates are properly aligned. Misregistration can cause blurring or ghosting of images and text. Look for crisp, sharp edges in printed images and text to confirm accurate alignment.

- Monitor Repeated Patterns: Repeating patterns or solid areas of color are especially prone to registration issues. Inspect these areas carefully for any signs of misalignment.

Ink Density and Coverage

- Monitor Ink Levels: Ensure that ink density remains consistent across the entire sheet. Uneven ink coverage can cause some areas to appear too light or too dark. Use densitometers to measure ink density and compare it to the required levels.

- Avoid Over-inking: Check for setoff (wet ink transferring onto other sheets), particularly in areas of heavy ink coverage. Ink smudging indicates that ink density is too high, or drying time needs adjustment.

About Huaxin

A family business founded in 1988 with three generations involved, Huaxin Printing has been devoting all its effort to print hardcover books with the highest possible quality.

Hua Xin has been certified with ISO 9001:2015 as well as the FSC (Forest Steward Council), and has been audited by 4-Pillar Sedex for social compliance (SMETA).

Get in Touch

If you intend to print books, or simply want to know more about us, feel free to send us a message.